Realtime Production Monitoring and Reporting

• Published 9:00 AM EDT, Fri Nov 10, 2023

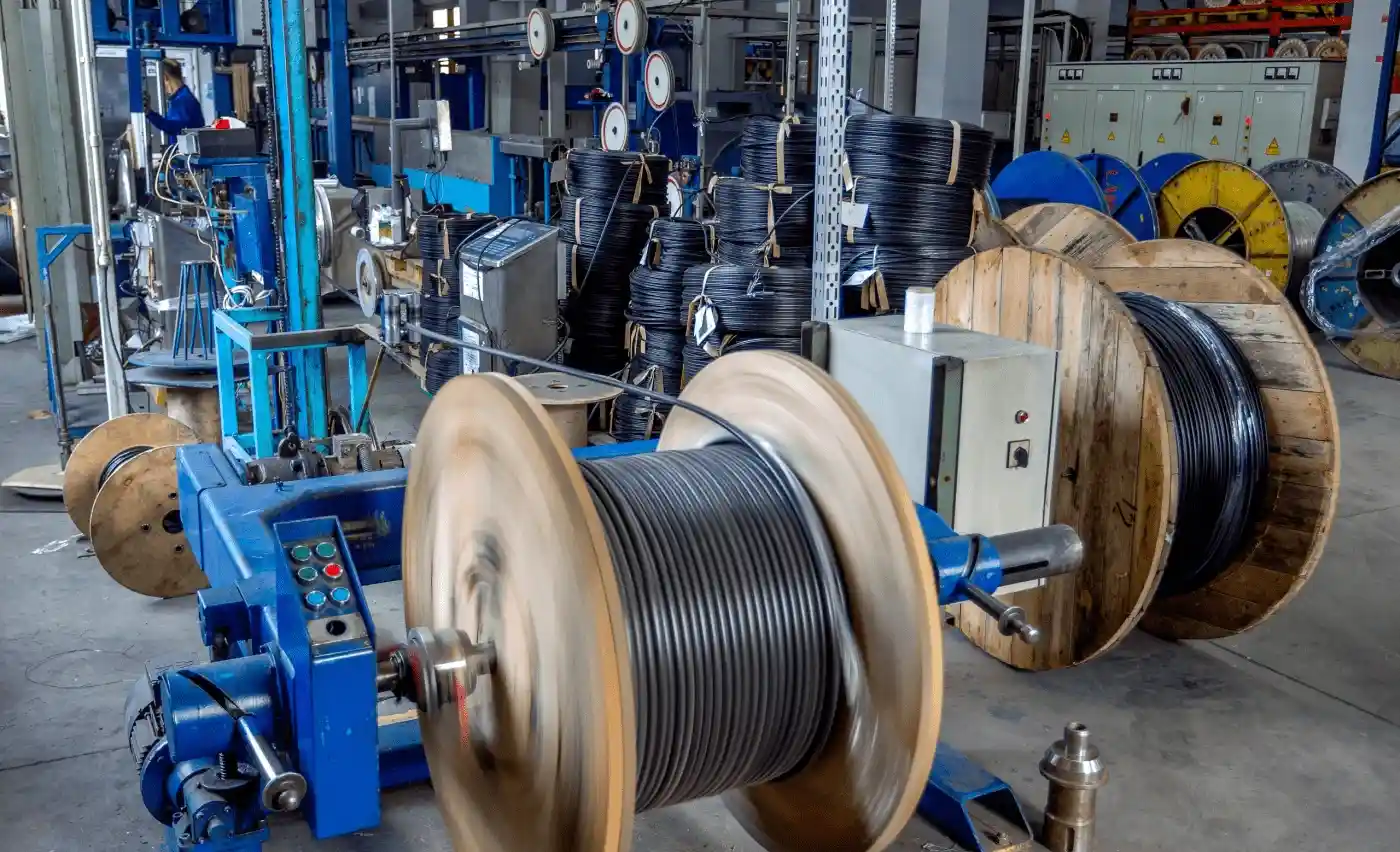

Monitoring the factory floor is essential to keep the production processes running smoothly and efficiently. But traditional monitoring can be challenging due to the complexity of production processes, the volume of data generated, the potential for interference with production processes, and the potential for human error. Switching to real-time monitoring enables organisations to continuously monitor the machines on the production floor, allowing for live immediate analysis and response.

Xeptagon IPS real-time monitoring is a proactive approach to production management, that allows organisations to identify and address issues immediately, minimize downtime and reduce the risk of production delays. Xeptagon IPS real-time monitoring is powered by easy-to-install, plug-and-play IoT integrations ensuring precise and accurate data collection from the factory floor. The data collected by our cutting-edge IoT is then processed and analysed in real-time to identify patterns, trends, and anomalies.

This enables your organisation to monitor the performance of the production floor through the current status and utilization of the machines. This is a useful tool to assess the overall efficiency of your production processes and identify areas where improvements can be made. The real-time information provided by Xeptagon IPS allows you to make informed decisions about how best to optimize production processes while diagnosing problems ensuring that you're able to operate at peak efficiency.

Xeptagon IPS Real-time monitoring through our interactive dashboard helps manufacturing organizations to:

- Identify problems on the production floor

- Detailed reports on machine utilization and idle times

- Help determine the cause of problems

- Improve process management efficiency

- Get notified of any anomalies

- Generate audit trail of factory activities

- Plan for machine capacity

The IoT devices employed by Xeptagon IPS can be connected to multiple machines in your factory and its sensory system feeds the operational status of the factory machinery into the system in real-time. This information is then presented in a Dashboard that provides a visual overview of the factory floor of each of the manufacturing plants, showing the available equipment and their statuses.

The simplified statuses of whether a machine is running or not give the users a quick understanding of the situation on the factory floor. Furthermore, the activity of machines recorded can be accessed as utilization reports. The reports generate an audit trail that allows the organisation to track and verify activity. Utilization reports can be generated according to your requirements as daily, weekly or monthly. Numerous statistics provided through utilization reports are:

- Machine running timing with the activity details

- Machine use during office and out-of-office hours separately

- Machine Idle time

- System Down Time

In addition, the statistics generated can be easily customizable to generate innovative statistics as required by factories. The information is displayed in tabular and graphical formats for customizable time periods that can be compared with other time periods. This enables factory project managers to identify patterns, and issues and optimize production plans for higher output and production efficiency. Xeptagon utilizes state-of-the-art IoT devices sourced from globally reputed vendors. The IoT devices are well suited for harsh industrial environments as well as come with an international warranty by the manufacturer. Xeptagon IPS real-time monitoring can also be integrated with already existing IoT installations.

Stay competitive in today’s fast-paced business environment with our intelligent production scheduling software. Contact us today to learn more and take your production to the next level with Xeptagon IPS.

Read more details about the Xeptagon Intelligent Production Scheduling (IPS) System here.